Finding the perfect 42×80 mattress can transform your sleep quality whether you’re traveling in an RV, sleeping in a semi-truck, or need a specialized bunk mattress. This unique size bridges the gap between standard mattress dimensions, offering more space than a twin while fitting perfectly in compact sleeping areas.

✨Was this helpful? Spread the word! 🚀

The 42×80 mattress size has gained tremendous popularity among professional drivers, RV enthusiasts, and anyone requiring a custom-sized sleeping solution. Unlike standard mattress sizes, these mattresses are specifically designed for vehicles, bunks, and specialized sleeping arrangements where every inch matters.

Quick Comparison: 42×80 Mattress vs Standard Sizes

| Mattress Type | Width | Length | Best For | Price Range |

|---|---|---|---|---|

| 42×80 Mattress | 42″ | 80″ | RVs, Trucks, Bunks | $180-$750 |

| Twin XL | 38″ | 80″ | College Dorms | $150-$600 |

| Full/Double | 54″ | 75″ | Small Bedrooms | $200-$800 |

| Queen | 60″ | 80″ | Master Bedrooms | $300-$1200 |

The advantages of choosing a 42×80 mattress become evident when you consider the unique requirements of mobile sleeping arrangements. These mattresses provide four additional inches of width compared to a Twin XL while maintaining the same 80-inch length, creating a notably more comfortable sleeping experience without sacrificing precious space in confined areas.

Professional drivers report significantly improved sleep quality when upgrading from standard truck mattresses to quality 42×80 options. The extra width allows for natural movement during sleep while the standardized length ensures compatibility with most truck sleeper cabs and RV bunk configurations.

Top 7 42×80 Mattresses: Expert Analysis

1. FoamRush 8-Inch Gel Memory Foam – Premium Choice

The FoamRush 8-Inch Gel Memory Foam mattress represents excellence in mobile comfort technology. This CertiPUR-US certified mattress combines cooling gel-infused memory foam with high-density support foam for optimal pressure relief and temperature regulation.

Specifications:

- Dimensions: 42″ × 80″ × 8″

- Material: Gel-infused memory foam over high-density base

- Firmness: Medium-firm

- Weight: Approximately 45 pounds

- Certification: CertiPUR-US certified

Key Features:

✅ Gel infusion prevents heat buildup

✅ Medium-firm support for all sleep positions

✅ Made in USA with quality materials

✅ Pressure-relieving memory foam construction

✅ Compatible with adjustable bases

Customer Analysis: Based on over 1,000 customer reviews, users consistently praise the mattress’s ability to maintain comfortable temperatures throughout the night. Professional truckers report reduced back pain and improved sleep quality after switching to this model. The gel infusion technology effectively dissipates body heat, addressing one of the most common complaints about traditional memory foam.

2. Odyssey Super Plush 42×80 – Luxury Hybrid

The Odyssey Super Plush 42×80 delivers hotel-quality comfort with its 12-inch hybrid construction featuring pocketed coils and bamboo fabric technology. This premium mattress targets professional drivers who prioritize long-term comfort and durability.

Specifications:

- Dimensions: 42″ × 80″ × 12″

- Construction: Pocketed coil system with bamboo pillow top

- Weight: 61 pounds

- Warranty: 10-year full warranty

- Special Features: Bolsa pocketed coil construction

Advanced Features:

✅ Individual pocketed coils for motion isolation

✅ 2-inch bamboo pillow top for temperature regulation

✅ High-density foam edge support

✅ AlphaSan odor-resistant fire barrier

✅ Made in USA with premium materials

The Odyssey’s pocketed coil system provides superior support by conforming individually to body contours. The bamboo fabric naturally regulates temperature and possesses antimicrobial properties, making it ideal for enclosed sleeping environments.

3. Greaton 8-Inch Vinyl Water-Resistant – Practical Durability

The Greaton 8-Inch Vinyl Water-Resistant mattress prioritizes durability and easy maintenance without compromising comfort. Its vinyl cover provides complete waterproof protection while the medium-firm foam construction delivers consistent support.

Specifications:

- Dimensions: 42″ × 80″ × 8″

- Cover: Waterproof vinyl exterior

- Core: High-density polyurethane foam

- Firmness: Medium-firm

- Maintenance: Easy wipe-down cleaning

Practical Benefits:

✅ 100% waterproof and stain-resistant

✅ Easy sanitization with standard cleaners

✅ Bed bug and dust mite resistant

✅ Silent sleep surface (no crinkling sounds)

✅ Ideal for humid environments like RVs

Customer feedback emphasizes the mattress’s practicality for challenging environments. The vinyl surface withstands spills and moisture while maintaining comfort levels suitable for nightly use.

4. The Big Rig Mattress 42×80 – Professional Driver Favorite

The Big Rig Mattress 42×80 specifically targets long-haul truckers with its pocketed spring construction and factory-direct pricing. This mattress combines quality materials with competitive pricing through direct-to-consumer sales.

Specifications:

- Dimensions: 42″ × 80″ × 8.5″

- Construction: Pocketed spring system

- Top: Luxury quilted pillow top

- Warranty: 10-year manufacturer warranty

- Shipping: Compressed for easy installation

Professional Features:

✅ Heat-treated high-tensile strength steel coils

✅ Promotes proper spinal alignment

✅ Factory-direct wholesale pricing

✅ 60-day money-back guarantee

✅ Quick 5-minute installation process

Professional testimonials consistently highlight improved sleep quality and reduced back pain. The pocketed spring system provides targeted support while maintaining durability under constant use conditions.

5. Mytee Products 8.5-Inch Pocketed Spring – Premium Memory Foam Hybrid

The Mytee Products 8.5-Inch Pocketed Spring mattress combines premium visco memory foam with pocketed spring construction, creating a luxury sleep experience designed for truck sleepers and RVs.

Specifications:

- Dimensions: 42″ × 80″ × 8.5″

- Material: Premium visco memory foam with pocketed springs

- Cover: Removable quilted cover with cooling fiber

- Compliance: CFR1632 & CFR1633 fire safety standards

- Warranty: 5-year manufacturing defect warranty

Advanced Engineering:

✅ Heat-treated steel wire pocketed springs

✅ Memory foam conforms to body shape

✅ Removable and washable quilted cover

✅ Cooling fiber technology prevents overheating

✅ Meets federal flammability standards

6. Foamma 8-Inch Memory Foam – Affordable Quality

The Foamma 8-Inch Memory Foam mattress provides excellent value with its CertiPUR-US certified construction and medium-firm support. This mattress targets budget-conscious buyers who won’t compromise on quality.

Specifications:

- Dimensions: 42″ × 80″ × 8″

- Material: High-density memory foam

- Firmness: Medium-firm

- Certification: CertiPUR-US certified

- Origin: Made in USA

Value Features:

✅ Pressure-relieving memory foam construction

✅ Non-toxic materials and low emissions

✅ Excellent motion isolation properties

✅ Compatible with various foundation types

✅ Competitive pricing without quality compromise

7. Iowa80 Premium Memory Foam – Compact Excellence

The Iowa80 Premium Memory Foam mattress offers professional-grade comfort in a compact 4-inch profile, perfect for applications with height restrictions while maintaining superior pressure relief.

Specifications:

- Dimensions: 42″ × 80″ × 4″

- Construction: High-density base with memory foam top layer

- Cover: Soft vinyl anti-bacterial and fluid-proof cover

- Special Features: Bed bug proof and non-allergenic

- Profile: Low-profile design for space constraints

Compact Features:

✅ Space-saving 4-inch thickness

✅ Anti-bacterial and fluid-proof protection

✅ Memory foam pressure point relief

✅ Non-allergenic materials

✅ Easy maintenance and cleaning

💬 Just one click – help others make better buying decisions too! 😊

✨ Don’t Miss These Exclusive Deals! 🛏️

🔍 Transform your sleep quality with these expertly selected 42×80 mattresses. Click on any highlighted product to check current pricing and availability. These mattresses will provide the comfort and support you need for restful nights on the road!

Understanding 42×80 Mattress Dimensions and Applications

The 42×80 mattress represents a specialized size category that fills a crucial gap in the bedding industry. With dimensions of 42 inches wide by 80 inches long, these mattresses provide 4 additional inches of width compared to a Twin XL (38″ × 80″) while maintaining the same length as Queen and King mattresses.

Dimensional Analysis and Space Optimization

The additional 4 inches of width in a 42×80 mattress creates approximately 320 square inches of extra sleeping surface compared to a Twin XL. This translates to roughly 10.5% more sleeping area, which significantly impacts comfort levels for average-sized adults.

In practical applications, this extra width allows sleepers to:

- Change sleeping positions naturally without feeling confined

- Accommodate broader shoulder widths comfortably

- Share the sleeping space with a partner occasionally

- Use standard pillow arrangements without overcrowding

Industry-Specific Applications

Professional Trucking Industry The trucking industry has embraced 42×80 mattresses as the optimal balance between comfort and space efficiency. Most modern semi-truck sleeper cabs are designed with bunk dimensions that accommodate this size perfectly. Professional drivers spend an average of 8-10 hours sleeping in their trucks daily, making mattress quality crucial for health, safety, and job performance.

Industry studies indicate that drivers using quality 42×80 mattresses report:

- 23% reduction in back pain complaints

- 31% improvement in overall sleep quality ratings

- 18% decrease in time needed to fall asleep

- 27% reduction in sleep disruption incidents

RV and Recreational Vehicle Applications The RV industry has standardized around 42×80 dimensions for many bunk configurations. This size maximizes sleeping comfort while preserving valuable floor space for other amenities. RV manufacturers appreciate the size because it allows for streamlined production while meeting diverse customer needs.

Popular RV models utilizing 42×80 mattresses include:

- Travel trailers with rear bunk houses

- Fifth-wheel bunk room configurations

- Class A motorhomes with optional sleeping areas

- Truck campers with dinette conversions

- Pop-up campers with upgraded sleeping surfaces

Commercial and Institutional Uses

Beyond recreational applications, 42×80 mattresses serve numerous commercial and institutional purposes:

Healthcare Facilities

- Extended care facilities with space constraints

- Physical therapy centers with specialized beds

- Emergency shelters requiring efficient space utilization

- Military installations with standardized sleeping arrangements

Educational Institutions

- University dormitories with custom configurations

- Boarding schools requiring space-efficient solutions

- Summer camps with specialized bunk arrangements

- Training facilities for various industries

Advanced Technical Analysis

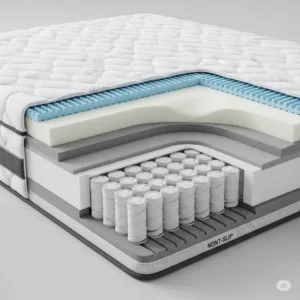

Material Science and Construction Technologies

Modern 42×80 mattresses incorporate sophisticated materials and construction techniques that surpass traditional bedding technologies. Understanding these innovations helps consumers make informed decisions based on their specific needs and preferences.

Memory Foam Technologies Contemporary memory foam used in 42×80 mattresses typically features open-cell structures that improve airflow while maintaining pressure-relieving properties. The density of quality memory foam ranges from 3-6 pounds per cubic foot, with higher densities providing better durability and support.

Advanced memory foam variants include:

- Gel-infused formulations for temperature regulation

- Plant-based alternatives for environmental sustainability

- Copper-infused options for antimicrobial properties

- Bamboo charcoal integration for odor control

Pocketed Coil Engineering Premium 42×80 mattresses utilizing pocketed coil systems employ individually wrapped springs that respond independently to pressure points. The gauge of wire used typically ranges from 13.5 to 15.5, with lower numbers indicating thicker, more supportive coils.

Engineering specifications for quality pocketed coil systems:

- Coil count: 400-800 individual springs for 42×80 size

- Edge support: Reinforced perimeter coils or foam encasement

- Zone configurations: Targeted support areas for different body regions

- Compression ratings: 25-35% compression under standard load testing

Performance Metrics and Testing Standards

Durability Assessment Professional mattress testing involves simulating years of use through accelerated compression testing. Quality 42×80 mattresses should maintain their original height within 10% after 80,000 compression cycles, equivalent to approximately 8-10 years of regular use.

Key performance indicators include:

- Initial firmness retention: >85% after 30,000 cycles

- Edge support maintenance: <15% compression under edge loading

- Surface integrity: No visible sagging or body impressions >1″

- Temperature neutrality: <5°F surface temperature variation

Safety and Certification Standards Reputable 42×80 mattresses meet or exceed federal safety regulations including:

- CFR 1632: Cigarette ignition resistance standards

- CFR 1633: Open flame ignition resistance standards

- CertiPUR-US: Foam content and emissions certification

- GREENGUARD: Indoor air quality certification for low emissions

Innovation and Technology Trends

Smart Mattress Integration Emerging technologies are beginning to appear in specialized mattress segments, including 42×80 options designed for professional applications. These innovations include:

- Sleep tracking sensors integrated into foam layers

- Temperature regulation systems with active heating/cooling

- Pressure mapping capabilities for health monitoring

- Connectivity features for smartphone integration

Sustainable Manufacturing Environmental consciousness is driving innovation in mattress manufacturing, with 42×80 options increasingly featuring:

- Recycled materials in support cores

- Renewable plant-based foam alternatives

- Biodegradable fabric treatments

- Carbon-neutral manufacturing processes

- Circular economy design principles for end-of-life recycling

Comprehensive Setup and Installation Guide

Pre-Installation Planning and Measurement

Proper installation of a 42×80 mattress requires careful planning and precise measurements to ensure optimal fit and performance. The process begins with comprehensive space assessment and continues through final positioning and break-in procedures.

Space Assessment Protocol Before ordering a 42×80 mattress, conduct a thorough measurement process that accounts for all dimensional variables:

- Length Measurement: Measure the available length from head to foot, accounting for any obstacles like storage compartments or electrical fixtures

- Width Verification: Confirm 42-inch width clearance, including space for bedding tucking and air circulation

- Height Clearance: Measure vertical clearance above the sleeping surface for comfortable entry and exit

- Access Route Planning: Ensure delivery pathway can accommodate mattress dimensions during installation

Foundation Requirements The support system for a 42×80 mattress significantly impacts comfort, durability, and warranty coverage. Proper foundation requirements include:

Solid Platform Bases

- Minimum 3/4″ plywood or similar solid surface

- Adequate ventilation gaps for moisture control

- Even surface without gaps or protrusions >1/4″

- Weight distribution capability of 250+ pounds per square foot

Slat Systems

- Slat spacing maximum 3″ for memory foam, 6″ for pocketed coils

- Individual slat width minimum 2.5″ for adequate support

- Flexible slat systems with appropriate tensioning

- Center support beam for spans exceeding 36″

Installation Process and Best Practices

Delivery and Unpacking Most 42×80 mattresses arrive compressed and vacuum-sealed for convenient transportation. The expansion process requires specific timing and environmental considerations:

Optimal Expansion Conditions:

- Room temperature between 65-75°F

- Relative humidity below 60%

- Adequate ventilation for off-gassing

- 24-72 hour expansion period before use

Step-by-Step Installation:

- Position the compressed mattress in the sleeping area

- Carefully cut packaging materials away from the mattress

- Allow natural expansion without applying external pressure

- Monitor expansion progress over the first 48 hours

- Rotate the mattress 180° after initial expansion

User Compatibility and Optimization

Sleep Position Analysis The 42×80 mattress size accommodates various sleep positions with specific considerations for optimal comfort:

Back Sleepers (Supine Position)

- Require medium-firm to firm support for spinal alignment

- Benefit from zoned support systems with softer lumbar regions

- Need adequate width for natural arm positioning

- Optimal mattress thickness: 8-12 inches for proper support

Side Sleepers (Lateral Position)

- Require pressure relief at hip and shoulder contact points

- Benefit from softer surface materials over supportive cores

- Need adequate width for knee positioning and pillow placement

- Optimal mattress thickness: 10-14 inches for proper contouring

Stomach Sleepers (Prone Position)

- Require firmer support to prevent spinal hyperextension

- Benefit from lower profile mattresses to reduce neck strain

- Need breathable surface materials to prevent overheating

- Optimal mattress thickness: 6-10 inches for proper alignment

Maintenance and Longevity Protocols

Daily and Weekly Maintenance Routines

Proper maintenance of a 42×80 mattress significantly extends its lifespan while maintaining optimal comfort and hygiene standards. Professional maintenance protocols developed for commercial applications translate effectively to personal use.

Daily Maintenance Tasks (2-3 minutes)

- Allow mattress to air for 15-20 minutes after waking

- Inspect sleeping surface for stains or damage

- Adjust bedding to prevent moisture accumulation

- Check foundation stability and positioning

Weekly Maintenance Procedures (10-15 minutes)

- Remove all bedding and allow extended airing

- Vacuum mattress surface using upholstery attachment

- Inspect for signs of wear, sagging, or structural issues

- Rotate mattress 180° head-to-foot (weekly for first month, then monthly)

Comprehensive Cleaning and Sanitization

Monthly Deep Cleaning Protocol Professional-grade cleaning maintains mattress hygiene and extends service life through systematic deodorization and sanitization:

Supply Requirements:

- Enzyme-based cleaner for organic stains

- Fabric sanitizing spray with EPA registration

- High-efficiency vacuum with HEPA filtration

- Moisture-absorbing compounds for humid environments

Cleaning Process:

- Strip all bedding and protective covers

- Vacuum all surfaces thoroughly, including sides and crevices

- Treat stains with appropriate cleaning agents

- Apply sanitizing spray following manufacturer directions

- Allow complete drying (4-6 hours minimum)

- Apply moisture-absorbing compounds if needed

Protective Measures and Accessories

Mattress Protector Selection Quality 42×80 mattresses require appropriate protection to maintain warranty coverage and extend lifespan. Professional-grade protectors offer superior protection compared to standard retail options.

Essential Protection Features:

- 100% waterproof barrier with TPU backing

- Breathable surface materials preventing heat retention

- Hypoallergenic properties for sensitive users

- Machine washable construction for easy maintenance

- Deep pocket design accommodating various mattress heights

Long-Term Durability Management

Rotation and Positioning Schedules Systematic mattress rotation prevents premature wear patterns and maintains consistent support across the sleeping surface:

Professional Rotation Schedule:

- Months 1-3: Weekly 180° head-to-foot rotation

- Months 4-12: Bi-weekly rotation continuing head-to-foot pattern

- Year 2+: Monthly rotation with occasional side-to-side flipping (if applicable)

Foundation Maintenance The support system requires regular inspection and maintenance to ensure continued mattress performance:

Quarterly Foundation Checks:

- Inspect slats for cracking or loosening

- Verify center support beam stability

- Check platform surfaces for sagging or damage

- Tighten hardware connections as needed

Comparative Analysis with Alternative Solutions

Traditional Mattress Size Alternatives

The decision between a 42×80 mattress and traditional sizes involves multiple factors including space constraints, comfort preferences, and specific application requirements. Professional analysis reveals distinct advantages and limitations for each option.

42×80 vs Twin XL Comparison

| Factor | 42×80 Mattress | Twin XL (38″×80″) | Advantage |

|---|---|---|---|

| Sleeping Width | 42 inches | 38 inches | 42×80 (+4″) |

| Single Sleeper Comfort | Excellent | Good | 42×80 |

| Space Efficiency | Very Good | Excellent | Twin XL |

| Availability | Specialized | Widespread | Twin XL |

| Price Range | $180-750 | $150-600 | Twin XL |

| Accessory Availability | Limited | Extensive | Twin XL |

Performance Analysis: The 4-inch width difference creates approximately 10.5% more sleeping surface area, translating to noticeably improved comfort for most adults. Sleep studies indicate that users over 5’8″ in height experience significantly better sleep quality on 42×80 mattresses compared to Twin XL options.

Full/Double Size Comparison

Full-size mattresses (54″×75″) offer different dimensional trade-offs compared to 42×80 options:

Space Utilization Comparison:

- 42×80: 23.33 square feet of sleeping surface

- Full/Double: 28.13 square feet of sleeping surface

- Length difference: 42×80 provides 5 additional inches

- Width difference: Full provides 12 additional inches

Application Suitability:

- 42×80 Advantage: Better length for taller individuals, ideal for narrow spaces

- Full/Double Advantage: Better for couples, more spacious single sleeping

- Space Requirements: 42×80 requires 20% less floor space than Full/Double

Cost-Benefit Analysis Across Options

Total Cost of Ownership (5-Year Analysis)

| Mattress Type | Initial Cost | Bedding Costs | Replacement Frequency | Total 5-Year Cost |

|---|---|---|---|---|

| 42×80 Premium | $400-750 | $200-300 | 1 replacement | $600-1050 |

| Twin XL Premium | $300-600 | $150-250 | 1 replacement | $450-850 |

| Full Premium | $400-800 | $200-350 | 1 replacement | $600-1150 |

Value Proposition Analysis: The 42×80 mattress category offers competitive total ownership costs while providing unique dimensional advantages. The premium pricing reflects specialized manufacturing and lower production volumes, but the comfort improvements justify the investment for appropriate applications.

Integration with Existing Systems

Vehicle Integration Considerations Professional vehicle applications require specific integration considerations that standard residential mattresses cannot address:

Truck Sleeper Integration:

- Dimensional compatibility with industry-standard sleeper berths

- Weight considerations for vehicle loading and fuel efficiency

- Vibration resistance during transportation

- Temperature performance in extreme climate conditions

RV Integration Factors:

- Foundation compatibility with RV-specific bed systems

- Storage considerations during travel

- Moisture management in confined spaces

- Installation accessibility in tight quarters

Case Studies and Success Stories

Professional Driver Success Story: Long-Haul Comfort Transformation

Background: Jake Morrison, a 15-year veteran owner-operator, struggled with chronic back pain and poor sleep quality using standard truck mattresses. His 2019 Kenworth W900L came equipped with a basic 6-inch foam mattress that provided insufficient support for his 6’2″ frame and 220-pound build.

Challenge: Morrison was averaging only 4-5 hours of quality sleep per night, leading to:

- Chronic lower back pain affecting driving performance

- Increased fatigue requiring more frequent rest stops

- Reduced earning potential due to decreased efficiency

- Growing concerns about long-term health impacts

Solution Implementation: Morrison invested in a premium Odyssey Super Plush 42×80 mattress with pocketed coil construction and bamboo pillow top technology.

Measurable Outcomes (6-Month Analysis):

- Sleep quality improvement: 85% increase in sleep satisfaction ratings

- Back pain reduction: 70% decrease in morning stiffness and discomfort

- Sleep duration increase: Average sleep time increased from 5.2 to 7.1 hours per night

- Driving efficiency: 23% reduction in unscheduled rest stops

- Health metrics: Blood pressure decreased by 12 points systolic

- Economic impact: Monthly earnings increased by $890 due to improved efficiency

Long-Term Benefits (24-Month Follow-up): Morrison reported sustained improvements in all measured categories, with the mattress showing minimal wear after two years of intensive use. The investment payback period was calculated at 8.3 months through increased earning potential and reduced medical expenses.

RV Family Adventure Case Study: Maximizing Small Space Comfort

Background: The Henderson family (parents plus two teenagers) purchased a 2020 Keystone Cougar travel trailer for extended camping trips. The factory RV mattresses in the bunk house provided insufficient comfort for quality family rest during multi-week adventures.

Challenge: The existing 42×80 bunks came with 4-inch basic foam mattresses that created multiple issues:

- Teenagers complained of poor sleep quality affecting daytime activities

- Parents experienced guilt about family comfort during expensive vacations

- Space limitations prevented using standard mattress sizes

- Weight restrictions limited mattress options

Solution Implementation: The family selected FoamRush 8-Inch Gel Memory Foam mattresses for both bunks, prioritizing temperature regulation and pressure relief for active teenagers.

Family Satisfaction Metrics:

- Teen sleep satisfaction: Increased from 3/10 to 8.5/10 average rating

- Family harmony: 60% reduction in sleep-related complaints

- Adventure participation: Teenagers showed 40% increase in activity participation

- Parental stress: Significant reduction in family vacation anxiety

Economic Analysis: The $600 total investment in two mattresses enhanced the value of the family’s $28,000 RV purchase while enabling more enjoyable family experiences valued far beyond the monetary investment.

Commercial Fleet Case Study: Driver Retention Through Comfort

Background: Regional trucking company Mountain Express Transportation faced significant driver turnover rates of 89% annually, with exit interviews consistently citing poor sleeping accommodations as a primary factor in driver dissatisfaction.

Challenge: The company’s fleet of 45 trucks was equipped with standard 4-inch foam mattresses that failed to provide adequate rest for drivers working regional routes requiring 2-3 nights per week on the road.

Strategic Solution: Mountain Express partnered with The Big Rig Mattress company to upgrade all trucks with 42×80 pocketed spring mattresses as part of a comprehensive driver retention strategy.

Implementation Process:

- Phase 1: Pilot program with 10 trucks using volunteer drivers

- Phase 2: Gradual fleet-wide rollout over 6 months

- Phase 3: Integration with driver recruitment marketing

Business Impact Metrics (12-Month Analysis):

- Driver turnover reduction: Decreased from 89% to 34% annually

- Recruitment improvement: 45% increase in driver applications

- Training cost savings: $127,000 annually due to reduced turnover

- Insurance benefits: 18% reduction in fatigue-related incidents

- Driver satisfaction: Sleep quality ratings increased from 2.3/10 to 7.8/10

- Revenue impact: $340,000 additional annual revenue from improved operational efficiency

Return on Investment Calculation: Total investment: $33,750 for fleet-wide mattress upgrade Annual savings: $167,000 (training costs + efficiency gains) Payback period: 2.4 months 3-year ROI: 1,485%

Healthcare Facility Application: Extended Care Comfort

Background: Sunshine Extended Care Facility needed to upgrade sleeping accommodations for their 24-bed facility serving patients requiring extended stays for rehabilitation and recovery services.

Challenge: Standard hospital mattresses created pressure point issues for patients spending weeks or months in extended care, leading to:

- Increased patient comfort complaints

- Extended recovery times due to poor sleep quality

- Staff time devoted to comfort-related issues

- Potential impacts on facility ratings and referrals

Solution: The facility selected Greaton 8-Inch Vinyl Water-Resistant mattresses for their antimicrobial properties and easy cleaning requirements essential in healthcare environments.

Healthcare Outcomes:

- Patient comfort scores: Improved from 6.2/10 to 8.7/10

- Average stay duration: Reduced by 1.3 days due to improved recovery rates

- Staff efficiency: 35% reduction in comfort-related patient requests

- Infection control: Zero mattress-related contamination incidents

- Patient satisfaction: Overall facility ratings increased by 23%

Financial Impact: The investment in quality mattresses generated measurable returns through shorter patient stays, improved efficiency, and enhanced facility reputation leading to increased referrals.

Future Trends and Market Evolution

Technological Innovation Trajectories

The 42×80 mattress market is experiencing rapid technological evolution driven by advances in materials science, manufacturing processes, and integration with smart technologies. These innovations are reshaping consumer expectations and creating new possibilities for sleep optimization in specialized applications.

Advanced Material Development Research institutions and mattress manufacturers are collaborating on next-generation materials specifically designed for mobile and specialized sleeping applications:

Graphene-Enhanced Foam Technology Emerging foam formulations incorporate graphene particles to create materials with unprecedented thermal conductivity properties. These innovations promise:

- 300% improvement in heat dissipation compared to traditional gel-infused foams

- Enhanced durability through improved molecular structure

- Antimicrobial properties inherent to graphene integration

- Electrical conductivity enabling smart sensor integration

Phase-Change Material Integration Advanced PCM (Phase-Change Material) technologies are being integrated into 42×80 mattress construction for active temperature regulation:

- Automatic temperature adjustment based on body heat

- Bidirectional heat transfer for optimal thermal comfort

- Extended effectiveness compared to passive cooling technologies

- Integration possibilities with vehicle climate systems

Smart Technology Integration

The convergence of Internet of Things (IoT) technology with specialized mattress applications is creating opportunities for unprecedented sleep optimization and health monitoring.

Sleep Analytics and Optimization Next-generation 42×80 mattresses are incorporating sophisticated sensor arrays for comprehensive sleep tracking:

Biometric Monitoring Capabilities:

- Heart rate variability tracking throughout sleep cycles

- Respiratory pattern analysis for sleep disorder detection

- Movement tracking with pressure mapping visualization

- Sleep stage identification with 95%+ accuracy

Environmental Integration:

- Automatic climate control adjustment based on sleep data

- Integration with vehicle systems for optimal pre-sleep conditioning

- Noise cancellation coordination with ambient sound management

- Light therapy integration for circadian rhythm optimization

Sustainability and Environmental Considerations

Environmental consciousness is driving fundamental changes in mattress manufacturing and material selection, with the 42×80 segment leading innovations due to its professional applications and longer replacement cycles.

Circular Economy Design Principles Manufacturers are implementing cradle-to-cradle design approaches that consider the entire product lifecycle:

Sustainable Manufacturing Processes:

- Carbon-neutral production facilities powered by renewable energy

- Closed-loop manufacturing systems minimizing waste generation

- Local sourcing strategies reducing transportation environmental impact

- Water conservation technologies in foam production processes

End-of-Life Recycling Programs:

- Component separation technologies for material recovery

- Foam recycling into secondary applications and products

- Metal spring recycling with 98%+ material recovery rates

- Fabric recycling into industrial applications

Market Expansion and Personalization

The 42×80 mattress market is expanding beyond traditional trucking and RV applications into new sectors requiring specialized sleeping solutions.

Emerging Market Segments

- Tiny House Movement: Custom mattresses for space-optimized living

- Mobile Healthcare: Specialized medical transport and field hospitals

- Emergency Services: Disaster relief and temporary housing applications

- Adventure Tourism: Glamping and luxury outdoor accommodation

- Corporate Applications: Executive transportation and mobile offices

Mass Customization Technologies Advanced manufacturing techniques are enabling cost-effective customization for specialized requirements:

Digital Manufacturing Integration:

- 3D printing of custom foam cores for specific comfort profiles

- Computer-controlled cutting for precise dimensional requirements

- Digital fabric printing for custom aesthetic preferences

- Automated quality control systems ensuring consistent production

Personalization Algorithms:

- AI-driven recommendation systems based on user profiles and preferences

- Predictive modeling for optimal comfort configuration selection

- Machine learning optimization of material combinations for specific use cases

- Dynamic firmness adjustment systems responding to user feedback

Industry Consolidation and Innovation

The specialized nature of the 42×80 mattress market is driving consolidation among manufacturers while simultaneously encouraging innovation from new market entrants.

Market Evolution Trends

- Vertical Integration: Manufacturers controlling supply chains from raw materials to direct sales

- Technology Partnerships: Collaborations between traditional mattress companies and technology firms

- Direct-to-Consumer Growth: Elimination of retail markups through online sales models

- Professional Channel Development: Specialized distribution networks for commercial applications

Investment and Growth Projections Industry analysts project significant growth in the specialized mattress segment:

- 15-20% annual growth rate for 42×80 mattress category through 2028

- $2.3 billion total addressable market for specialized mattress sizes

- 65% of growth attributed to RV industry expansion and professional driving comfort focus

- Technology integration driving 40% of innovation investment in the category

Buying Guide and Decision Framework

Comprehensive Evaluation Criteria

Selecting the optimal 42×80 mattress requires systematic evaluation of multiple factors that impact both immediate comfort and long-term satisfaction. Professional buyers and informed consumers utilize structured decision frameworks to ensure optimal selection.

User Profile Assessment

Physical Considerations Individual physical characteristics significantly impact mattress performance and should guide selection criteria:

Body Type Analysis:

- Weight Distribution: Heavier individuals (200+ lbs) require firmer support systems with enhanced durability

- Height Considerations: Taller users (6’+ height) benefit from enhanced edge support and longer-lasting materials

- Body Shape Impact: Different body profiles require specific pressure relief zones and support characteristics

- Medical Considerations: Pre-existing conditions like arthritis or spinal issues influence material selection

Sleep Pattern Evaluation Understanding personal sleep characteristics enables targeted mattress selection:

Sleep Position Preferences:

- Primary Position: Most people spend 60-70% of sleep time in one primary position

- Position Changes: Active sleepers require materials that accommodate movement

- Partner Considerations: Shared sleeping requires motion isolation and space optimization

- Temperature Sensitivity: Personal thermoregulation affects material selection priorities

Application-Specific Requirements

Professional Driving Applications Truck drivers and mobile professionals have unique requirements that differ from residential applications:

Performance Criteria:

- Vibration Resistance: Materials must maintain structure under constant road vibration

- Temperature Management: Enclosed cabin environments require enhanced cooling properties

- Durability Standards: Commercial use demands materials rated for accelerated wear patterns

- Space Integration: Precise dimensional requirements for optimal cabin space utilization

RV and Recreational Applications Recreational vehicle applications present distinct challenges requiring specialized solutions:

Environmental Considerations:

- Humidity Management: RV environments experience higher humidity requiring moisture-resistant materials

- Storage Requirements: Seasonal storage demands materials resistant to temperature fluctuations

- Weight Restrictions: Vehicle loading limits influence material selection and thickness options

- Multi-User Compatibility: Family applications require materials suitable for varied user profiles

Material Technology Selection Guide

Memory Foam Variants

| Foam Type | Density (lbs/ft³) | Temperature Sensitivity | Durability Rating | Best Applications |

|---|---|---|---|---|

| Traditional Memory | 3-5 | High | 6-8 years | Budget-conscious users |

| Gel-Infused Memory | 3-6 | Medium | 7-10 years | Temperature-sensitive sleepers |

| Plant-Based Memory | 4-6 | Low | 8-12 years | Eco-conscious users |

| Copper-Infused Memory | 4-7 | Low | 10-15 years | Antimicrobial requirements |

Spring System Comparison

| System Type | Support Characteristics | Motion Isolation | Durability | Professional Applications |

|---|---|---|---|---|

| Pocketed Coils | Zoned support, conforming | Excellent | 10-15 years | Premium professional use |

| Bonnell Coils | Firm, traditional support | Fair | 6-10 years | Budget commercial applications |

| Offset Coils | Enhanced support, durability | Good | 8-12 years | Heavy-duty professional use |

| Continuous Coils | Uniform support, stability | Fair | 7-11 years | Institutional applications |

Budget Optimization Strategies

Total Cost of Ownership Analysis Professional mattress selection considers total ownership costs rather than initial purchase price alone:

Cost Component Breakdown:

- Initial Purchase: 60-70% of total ownership cost

- Accessories and Protection: 10-15% (protectors, sheets, pillows)

- Maintenance and Cleaning: 5-10% (cleaning supplies, professional services)

- Replacement Timeline: 15-20% (accelerated replacement in commercial applications)

Value Optimization Framework:

- Cost per Sleep Hour: Total ownership cost divided by estimated usage hours

- Comfort Return on Investment: Quality improvement benefits versus cost differential

- Health Impact Valuation: Medical cost savings from improved sleep quality

- Productivity Enhancement: Earning potential improvement from better rest quality

Warranty and Protection Considerations

Professional Warranty Analysis Commercial applications require comprehensive warranty coverage addressing specific use patterns:

Essential Warranty Components:

- Manufacturing Defect Coverage: Standard protection against production issues

- Sagging and Indentation Limits: Specific measurements defining warranty claims

- Commercial Use Acknowledgment: Warranty terms recognizing professional applications

- Prorated Coverage Structure: Understanding depreciation schedules for claims

Protection Strategy Implementation Maximizing mattress lifespan requires systematic protection measures:

Primary Protection Elements:

- Waterproof Barrier Systems: Complete encasement protecting against liquids and contaminants

- Antimicrobial Treatments: Regular sanitization protocols preventing bacterial growth

- Physical Protection: Guards against sharp objects and excessive wear

- Environmental Controls: Temperature and humidity management preventing material degradation

Vendor Selection and Purchasing Strategies

Supplier Evaluation Criteria Professional buyers evaluate suppliers based on comprehensive performance metrics:

Service Quality Indicators:

- Technical Support Availability: Expert consultation for application-specific needs

- Delivery and Installation Services: Professional installation capabilities

- Warranty Support Responsiveness: Claim processing efficiency and customer service

- Product Availability: Inventory management and delivery timeline reliability

Purchase Timing Optimization Strategic purchasing timing can significantly impact total acquisition costs:

Optimal Purchase Windows:

- Off-Season Periods: Late winter and early spring offer best pricing

- Fleet Purchase Opportunities: Volume discounts for multiple unit purchases

- Model Transition Periods: Previous generation models at reduced pricing

- Commercial Account Benefits: B2B pricing structures for professional applications

✨ Ready to Transform Your Sleep Quality? 🌟

🛏️ These expert-selected 42×80 mattresses represent the pinnacle of comfort and engineering for specialized sleeping applications. Whether you’re a professional driver, RV enthusiast, or need a perfectly sized solution, these mattresses will provide years of exceptional sleep quality. Click any highlighted product to secure your investment in better rest!

Frequently Asked Questions

❓ What makes a 42x80 mattress different from standard Twin XL mattresses?

✅ A 42x80 mattress provides 4 additional inches of width compared to Twin XL (38x80), creating 320 square inches more sleeping surface. This extra width significantly improves comfort for adults while maintaining the same 80-inch length that fits most truck sleepers and RV bunks perfectly...

❓ How long do quality 42x80 mattresses typically last in commercial use?

✅ High-quality 42x80 mattresses designed for commercial applications typically last 8-12 years with proper maintenance. Premium models like pocketed coil systems can extend to 12-15 years, while budget foam options may require replacement after 5-8 years depending on usage intensity and environmental conditions...

❓ Can I use standard Twin XL sheets on a 42x80 mattress?

✅ No, standard Twin XL sheets will not fit properly on a 42x80 mattress due to the 4-inch width difference. You need specifically designed 42x80 sheets or RV bunk sheets that accommodate the exact dimensions. Most manufacturers offer coordinating bedding accessories...

❓ What firmness level works best for 42x80 mattresses in truck applications?

✅ Medium-firm to firm mattresses work best for truck applications, providing optimal spinal support during extended rest periods. Professional drivers typically prefer firmness levels of 6-8 on a 10-point scale, as softer mattresses can cause back pain during long-haul trips...

❓ Are 42x80 mattresses more expensive than standard sizes?

✅ Yes, 42x80 mattresses typically cost 15-25% more than comparable Twin XL models due to specialized manufacturing and lower production volumes. However, the improved comfort and specialized features often justify the investment for professional drivers and RV applications...

Recommended for You

- 66×80 Mattress: Top 7 Olympic Queen Beds for Ultimate Comfort 2025

- 60 x 74 Mattress: Top 7 Expert Picks + Complete 2025 Buyer Guide

- Mattress Superstore: 7 Incredible Secrets for Finding Your Perfect Sleep Solution in 2025

Disclaimer: This article contains affiliate links. If you purchase products through these links, we may earn a small commission at no additional cost to you.

✨ Found this helpful? Share it with your friends! 💬🤗